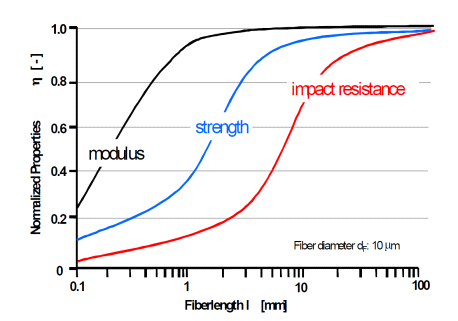

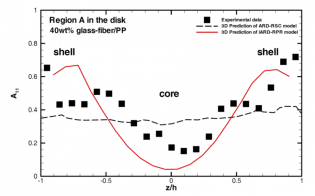

In recent years, long fibers are already widely used in automotive, consumer, and industrial applications. The practice of adding glass and carbon fibers into plastic materials reinforces the mechanical and thermal properties with little change of weight. A qualitative relationship between the fiber length and the mechanical properties of a glass fiber reinforced plastic is shown in Figure 1. The maximum strength and the impact properties could be dramatically increased by raising the fiber length. However, these fiber-related improvements to the part’s mechanical properties are heavily dependent on the fiber’s orientation. For example, shear flow introduces anisotropic properties to the injection-molded parts due to the preferential orientation of fibers induced by the flow during this processing. This is ideal for a part requiring larger strength and stiffness properties in the direction along the fibers than crossing the fiber. However, there are some cases in which random fiber distribution is desired to prevent non-uniform part warpage or shrinkage. In order to determine the performances of injection-molded parts and aid the design of the mold, part, and the processing conditions, the fiber orientation must be accurately predicted. You can find out more detailed short fiber orientation simulation validation in one of our technical papers presented in the Conference Paper section of this issue. Moldex3D’s new long fiber orientation prediction package featured in Moldex3D R11 offers a new solution in determining the orientation of short and long fiber-reinforced thermoplastic composites. Traditional fiber orientation models using the anisotropic rotary diffusion (ARD) technique based on Folgar-Tucker model could accurately perdict the fiber orientation. However the ARD technique requires 5 parameters and an inefficient computation method. Moldex3D R11 takes a major leap forward by developing the Improved Anisotropic Rotary Diffusion (iARD) technique (US patent pending). Combined with the Retarding Principal Rate (RPR) model, the iARD model provides accurate fiber orientation prediction and fast computation times. Features include: Moldex3D’s accuracy is exemplified in Figure 2, using a center-gated disk model. The A11 orientation tensors of both observed and predicted data shows a preferred orientation (large A11 value) near the wall while there is random distribution (A11 near 0) in the center. The conventional model falls short in predicting this important behavior. With Moldex3D’s latest technology in predicting short/long fiber orientation, designers and molders can gain a better control over their product quality. For more information regarding fiber orientation demonstrations and case studies, please go to our website www.moldex3d.com to learn about our exciting new functions and applications. Electric Utility Vehicle,Mini Electric Utility Vehicle,Yamaha Electric Utility Vehicle,Miniature Rideable Trains Shaanxi Green Enjoyment New Energy Technology Co., Ltd. , https://www.greenjoyev.com Fig. 1  Composite property improvement with increasing fiber length

Fig. 1 Â Composite property improvement with increasing fiber length

Source: Plasticomp

Fig. 2  Moldex3D’s long fiber simulation result (iARD, red line) shows an ideal agreement with observed data when compared to conventional ARD model (dotted line)

Fig. 2  Moldex3D’s long fiber simulation result (iARD, red line) shows an ideal agreement with observed data when compared to conventional ARD model (dotted line)