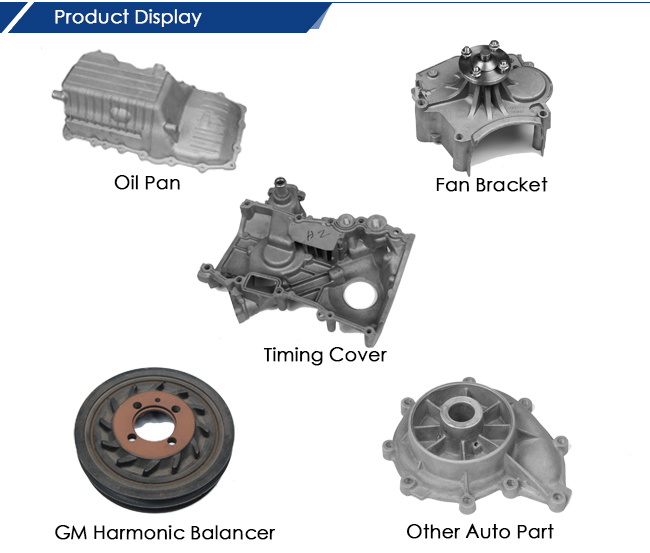

Our main products:Â Oil Pan, Auto Parts, Casting, Die Casting...

PVC Ceiling Panel Machine is used to produce PVC ceiling wall panel with different size, such as 200mm, 250m,300mm, 400mm, 600mm and so on. it is beglon to plastic extruder, used for Plastic Profile Extrusion Machine

Production flow of PVC ceiling production line:

Material batching mixing-extruding-molding-vacuum calibrating and cooling-hauling-cutting- final PVC ceiling

Surface treating ways:

hot stamp printing

high glossy printing

lamination by decoration film

The basic machines needed for production of PVC ceiling wall panel:

PVC panel extrusion line

(Including autoloader, conical twin screw extruder, mould, vacuum calibration chamber, hauling machine, auto cutter- stacker)

hot stamp printer or two color printing line or lamination

PVC pipe crusher& PVC miller

Air compressor

- Water chiller (optional)

- high glossy two color PVC ceiling wall panel printing line

Production flow of PVC ceiling production line:

Material batching mixing-extruding-molding-vacuum calibrating and cooling-hauling-cutting- final PVC ceiling

Surface treating ways:

hot stamp printing

high glossy printing

- lamination by decoration film

PVC mixer

PVC panel extrusion line

(Including autoloader, conical twin screw extruder, mould, vacuum calibration chamber, hauling machine, auto cutter- stacker)

hot stamp printer or two color printing line or lamination

PVC pipe crusher& PVC miller

Air compressor

Water chiller (optional)

high glossy two color PVC ceiling wall panel printing line

Pvc Ceiling Panel Machine,Pvc Ceiling Machine,Pvc Ceiling Making Machine, pvc ceiling extrusion line zhangjiagang sevenstars machinery co.,ltd , https://www.sevenstarsmachinery.com

Product

Oil pan

Material

metal

Certificate

ISO/TS16949

Applicable cylinder

Multi-cylinder

Applicable engine

Gasoline

Processing

Precision Metal Stamping Parts

Color

Custom

Size

Base on Your Requirement

Place of Origin

Zhejiang

Payment

T/T

Company information

Maisheng Machinery Manufacturing Co., Ltd.  has the Knowledge,experience and facilities to make your molds qualified at every making process.We work close with you through all phases of the whole process to make sure all issues are addressed properly, from project estimation, part function and design, steel material selection, mold layout and design, and mold making process, and cost analysis factors.

From small size to big size mold over 2000mm, from simple to complex mold such as auto heater part mold. As so many big and small precise facilities in house, so we are able to provide you good quality with reasonable price, and fast deliver time, and our professional project team will keep you good service always.

FAQ

Q1:Are you trading company or manufacturer ?

A: We are located in No. 556, Kangzhuang South Road, Jiangbei District, Ningbo City, Zhejiang, China(Mainland). Specialized in manufacturing of automobile parts.

Â

Q2:What is your main product?

A:We main Oil Pan, Auto Parts, Casting, Die Casting.

Â

Q3:What is your company specialized in?

A:Auto parts plastic injection mold making

Medicinal parts mold making

Home appliance part mold making

Industry parts mold making

Â

Q4:Why should we choose you?

A:We have 18 years experience in the business of all kinds of mould making. Good quality,reasonable lower price,fast delivery are also our advantage.

And we have a complete production line: processing center, big-sized NC milling machine, NC milling & drilling machine, diverse NC turning machine.

We also have a professional team for mold desige about ODM or OEM.

Â

Q5:How can we contact you?

A:Here is contact information:

Contact company:Ningbo Maisheng Machinery Manufacturing Co., Ltd.

Fax: +86 0574 87320428

Direct phone:Â +86 0574 87320438

Website: http://www.nbmachinery.com

Model NO.: OP106

The basic machines needed for production of PVC ceiling wall panel: